Choosing Between Disposable and Reusable Gloves: What You Need to Know

Disposable vs. Reusable Gloves: Which One's Right for You?

When it comes to choosing between disposable and reusable gloves, it is essential to consider the context and purpose of their use. Disposable gloves are mostly designed for single-use applications, providing a quick and cost-effective solution for situations requiring frequent glove changes, such as in medical or food service settings. These gloves help maintain high hygiene standards by minimizing cross-contamination risks.

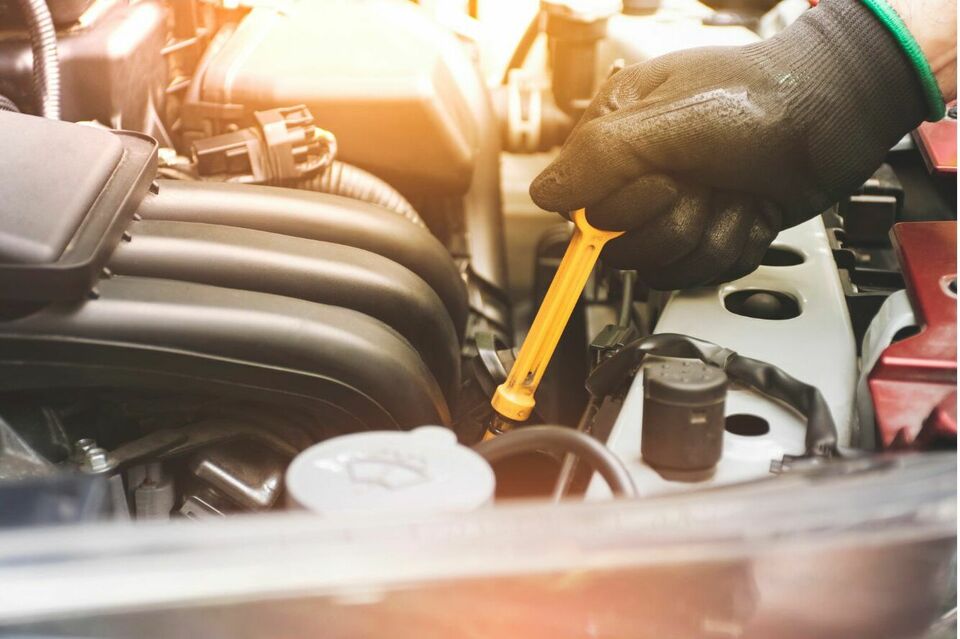

On the other hand, reusable gloves, are intended for multiple uses and are well-suited for tasks that demand robustness, such as construction, manufacturing and landscaping to name but a few. Ultimately, the choice between disposable and reusable gloves depends on the specific requirements of the task, including frequency of use and level of protection needed.

DISPOSABLE GLOVES:

Disposable gloves serve as a critical barrier in protecting the wearer's hands from various potential hazards, ranging from biological contaminants to mild chemicals.

These gloves are engineered to offer a balance between protection and functionality. Unlike their heavier, more durable counterparts, disposable gloves are prized for their ability to maintain a high level of touch sensitivity and dexterity.

This feature is particularly important in fields requiring precision and care, such as medical procedures, laboratory work, and culinary preparation. Their thin material, while not impervious to all substances, allows users to perform tasks with a near-natural feel, an essential factor in delicate operations.

However, it's crucial to understand the limitations of disposable gloves in terms of chemical resistance. They are specifically designed for incidental contact with chemicals rather than prolonged exposure or immersion.

This means that in environments where chemical spills or splashes are a risk, gloves should be promptly replaced after contamination to ensure continued protection.

The nature of these gloves as a single-use item underlines the importance of not attempting to reuse them, as their protective qualities diminish significantly after initial use, and contamination risks increase.

Moreover, when dealing with aggressive or highly hazardous chemicals, or in situations where there is a risk of physical damage to the gloves, such as tears or punctures from sharp objects, disposable gloves may not offer adequate protection.

In these scenarios, alternative forms of hand protection, designed for higher durability and specific chemical resistance, should be considered.

This emphasizes the need for a thorough risk assessment in choosing the appropriate type of hand protection for any given task, ensuring the safety and well-being of the wearer in a variety of working environments.

RE-USABLE GLOVES:

Re-usable gloves, with their thickness ranging between 457 and 711 microns, serve as a robust barrier against a variety of workplace hazards. Their durability surpasses that of disposable gloves, offering enhanced protection against abrasion and other physical damages.

Moreover, re-usable gloves are less prone to tearing, providing a reliable safeguard for the hands during demanding tasks.

There are some that offer a chemical resistance, which is notably stronger compared to disposable counterparts, although this attribute heavily relies on the specific materials and construction of the glove.

This feature is particularly valuable in environments where exposure to hazardous chemicals is a concern, as it ensures the user's safety by preventing harmful substances from coming into contact with the skin.

However, the trade-off for their durability and protective capabilities is a decrease in flexibility and touch sensitivity.

Re-usable gloves are generally stiffer, which may hinder fine motor skills and affect the user's ability to perform tasks that require a high degree of dexterity. This characteristic makes them less suited for precision work where touch sensitivity is paramount.

To maintain the protective qualities and extend the lifespan of re-usable gloves, proper care is essential. Regular cleaning and drying after each use are crucial steps in preventing skin contamination and preserving the integrity of the glove.

Especially after exposure to chemicals, it's important to thoroughly wash both the outside and the inside surfaces to remove any residues that could compromise safety or degrade the material over time.

The longevity of re-usable gloves necessitates vigilant maintenance and routine inspections for signs of wear and tear. Before each use, checking for discoloration, cracks, or any form of damage is imperative to ensure the gloves still provide adequate protection.

Any evidence of deterioration or internal contamination warrants immediate disposal of the gloves to avoid risking personal health or safety. Adhering to these maintenance guidelines not only maximizes the protective benefits of re-usable gloves but also contributes to a safer and more efficient work environment.

Posted: Monday 22 April 2024